|

|

|

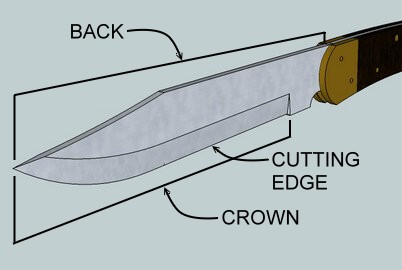

bench knife or a pocket knife may look simple, but these common tools

are the results of thousands of years of careful engineering. The

back keeps the knife stiff, while the wedge-shaped blade tapers down

to a low-angle cutting edge. This edge often has a curve or

crown that helps you control the cut.

bench knife or a pocket knife may look simple, but these common tools

are the results of thousands of years of careful engineering. The

back keeps the knife stiff, while the wedge-shaped blade tapers down

to a low-angle cutting edge. This edge often has a curve or

crown that helps you control the cut.And despite its apparent

simplicity, a knife can be deceptively complex to sharpen. Not only is

the profile often curved, the cutting

edge is ground along the side of the blade rather than the tip. Additionally,

the cutting edges of most knives have two bevels and must be ground from both sides. Because of this, many craftsmen find it easier to hold the knife in their hands as they

sharpen, maintaining the tool angle by eye. |

|

Sharpening Knives

|

|

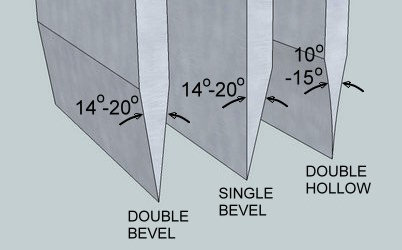

1 The most common way to grind

the cutting edge of a knife is to make a double bevel –

sharpening both surfaces of the blade at the same angle. This produces

the most serviceable and durable edge. You can also make a single

bevel – grinding one surface flat and creating a bevel on the other

edge. This is easier to maintain but not as serviceable. Depending on

what you're cutting, you may need to pay attention to which way the

bevel is facing. Or you can grind a double hollow in the edge

using a grinding wheel. This produces a more acute angle, but the

cutting edge is not as durable.

|

|

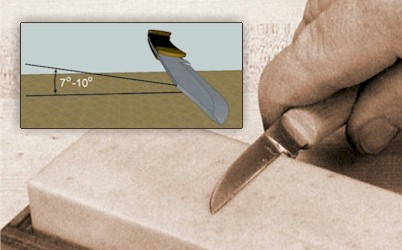

2

To sharpen a knife on a bench stone, hold it roughly perpendicular to

the length of the stone as you move it across the surface. Lock your

wrist to maintain the angle. For double-bevel edge, that angle should be

one half of the desired cutting angle. If the cutting edge is crowned,

wipe the knife sideways across the stone as you're pulling or pushing it

along the length. After sharpening one side of the bevel,

turn the knife over and repeat for the other side.

|

3

To sharpen a knife on an abrasive wheel, lock your wrist at the desired

angle and wipe the blade across the circumference, moving parallel to

the wheel’s axis. Use light pressure to keep from removing too much

metal. Repeat for each side of the bevel.

|

|

Back to the top

|

|

|

|