|

|

|

he steps for sharpening

skew chisels and

gouges are

roughly the same as they are for flat chisels. First, flatten the back

of the skew or the pod (concave curve) of the gouge. Thereafter, sharpen

the bevel, working your way up through finer and finer abrasives.

Finally, remove the burr that forms at the cutting edge. he steps for sharpening

skew chisels and

gouges are

roughly the same as they are for flat chisels. First, flatten the back

of the skew or the pod (concave curve) of the gouge. Thereafter, sharpen

the bevel, working your way up through finer and finer abrasives.

Finally, remove the burr that forms at the cutting edge.

However, because the shapes

of these tools are more complex than flat chisels, it’s harder to

maintain the bevel angle. You must either feel the angle

or devise some method of holding the

blade.

|

|

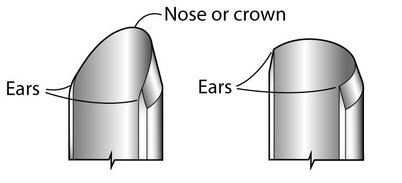

Turners often grind back the ears on the

shaping gouges they use to create spindles and bowls. This lets

them cut concave shapes. Roughing gouges, on which the ears

remain even with the nose, are used to round stock.

|

Sharpening a skew

|

|

1

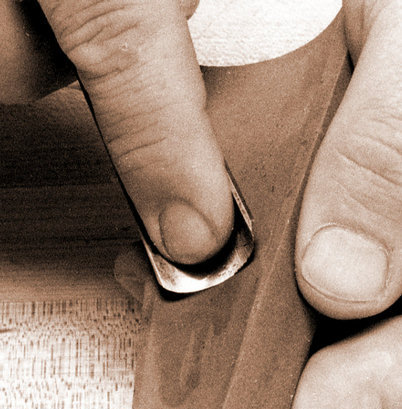

When sharpening a skew by hand, you must grind without the benefit of a

guide. Feel for the correct angle, resting the bevel flat on the stone.

Then lock your wrist in place to maintain that angle as you sharpen. If

you have trouble feeling the angle on a large stone, try a smaller slip

stone. Press the stone against the bevel with your fingertips. |

2

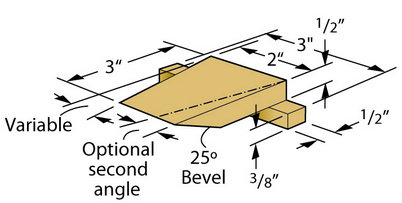

When sharpening a skew on a sharpening

machine, make a guide block with an angled side and clamp it to the tool

rest. Hold the side of the chisel against the angled side as you work.

The angle of the tool rest controls the bevel angle, and the angled side

of the block controls the skew angle. NOTE: When sharpening a

skew chisel with a double bevel, such as a lathe skew, make a guide

block with two angled sides, each side a mirror image of the other.

|

Sharpening a gouge

|

|

1

When hand sharpening a gouge, use a gouge slip. The rounded surfaces on

the stone fit the curved cutting edge and pod of the tool. Put your

fingertips in the pod opposite the bevel to help feel the angle.

|

2

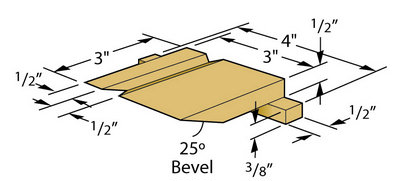

To sharpen a gouge on a sharpening machine, make a guide block with a

V-groove and clamp it to the tool rest. Rest the blade of the gouge in

the V and hold it there as you roll the tool from side to side. Press

the tool forward gently to keep the cutting edge against the abrasive as

the gouge rolls.

|

3

After finishing the bevel, use a round stone file to remove the burrs

from the cutting edge of a gouge. Lightly stroke the concave surface of

the pod with the file.

|

|

|

Back to the top

|

|

|