CHECK THE SETUP

Whenever you change or sharpen the jointer knives, check their height relative to the outfeed table. At the top of their rotation, they should be almost dead even with the table surface, maybe just 0.001 to 0.003 inch above it. If they’re too high or too low, you can’t make a straight cut. Too high, and the jointer will make a slightly concave cut; too low and the cut will be convex.

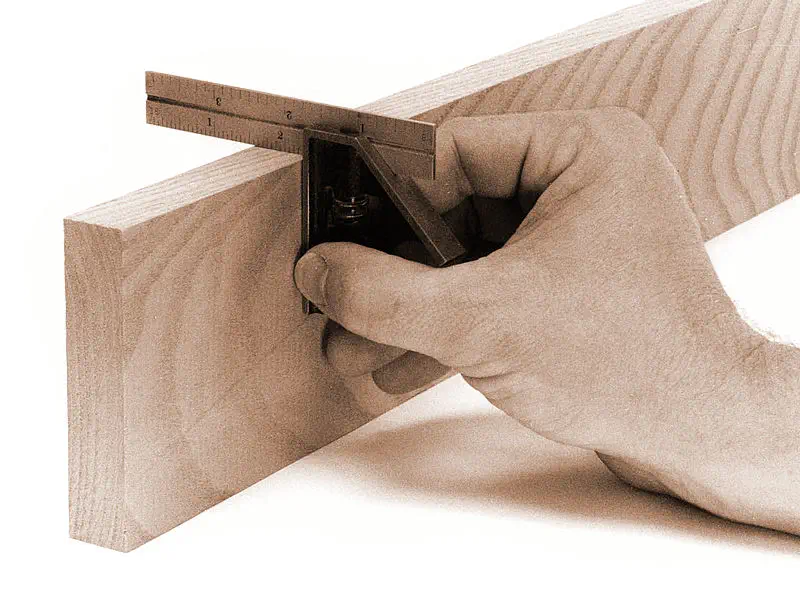

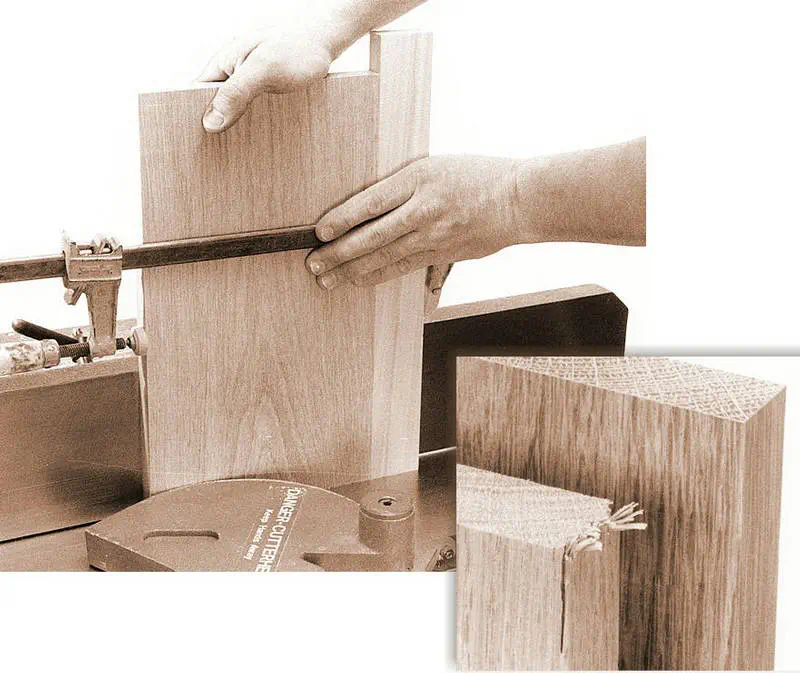

Whenever you move the fence, check its angle to the tables with a square or protractor. I also suggest doing this whenever you set up to prepare lumber for a project or do a lot of jointing tasks even if you haven't moved the fence. It's impossible to underestimate the amount of grief this simple precaution can save.

CHECKING THAT THE JOINTER MAKES STRAIGHT CUTS

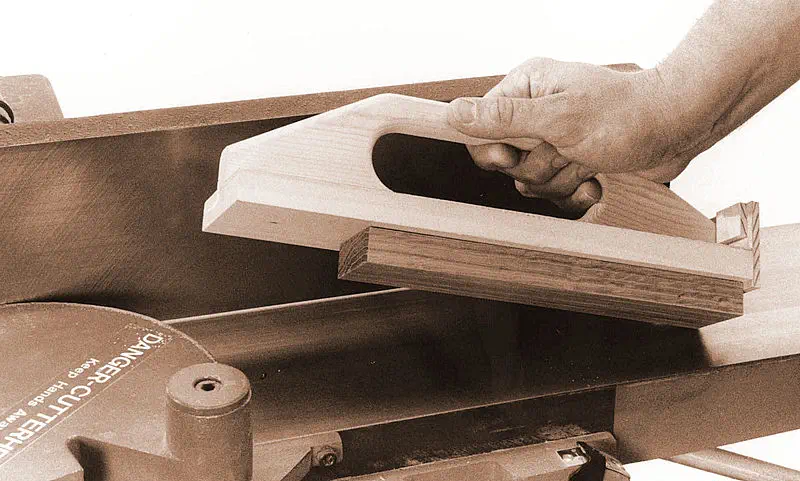

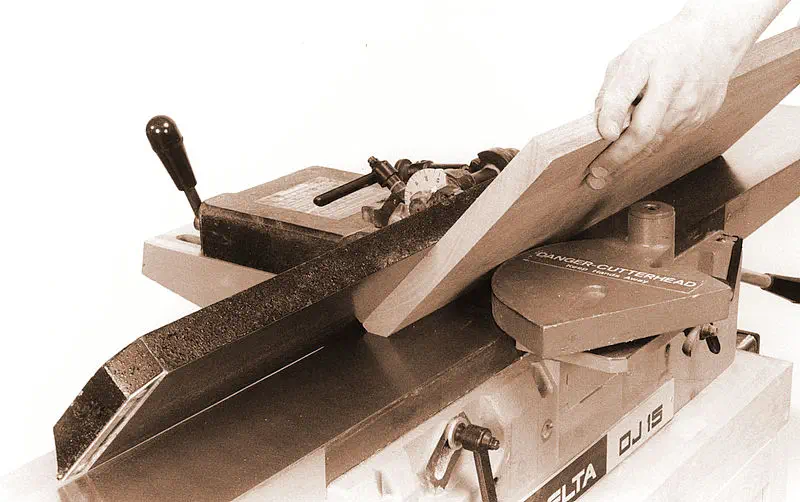

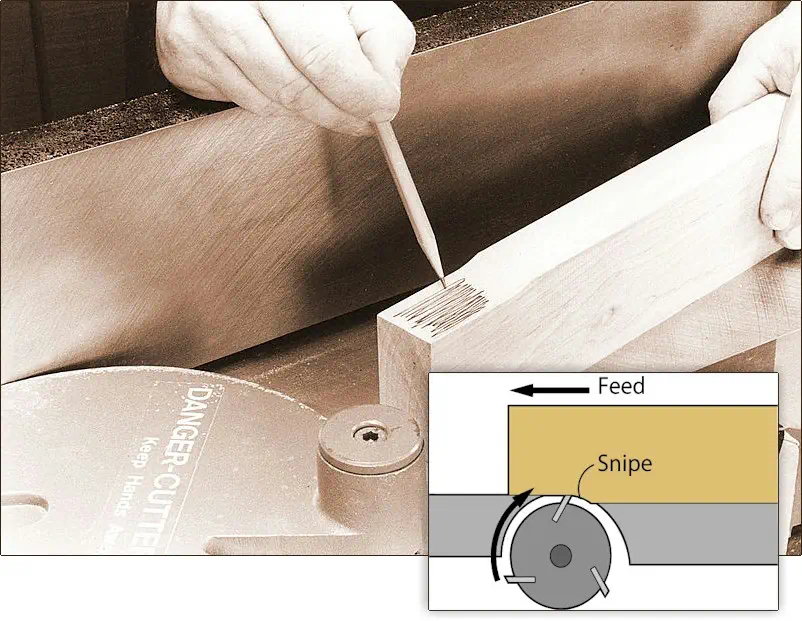

1 To check that your jointer is cutting a straight edge, joint the first 1 or 2 inches of a test board to create a snipe in the edge. Shade the snipe with a pencil.*

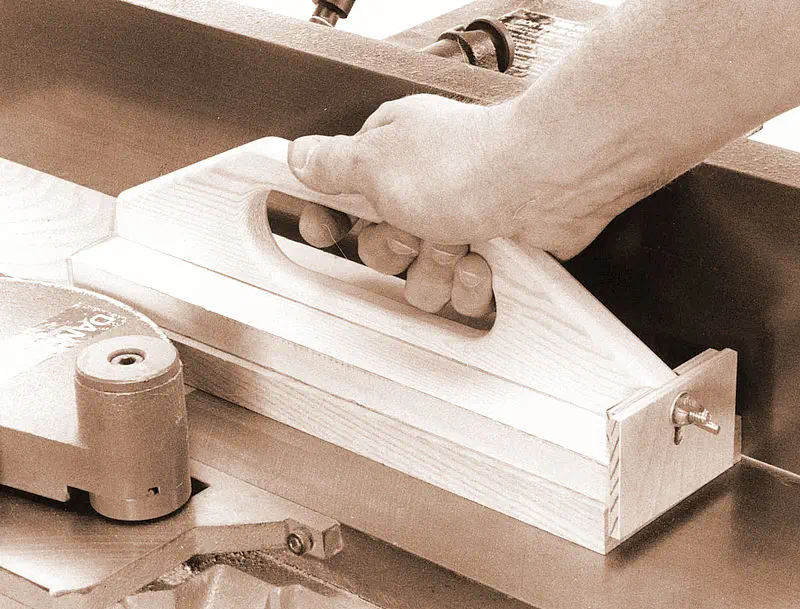

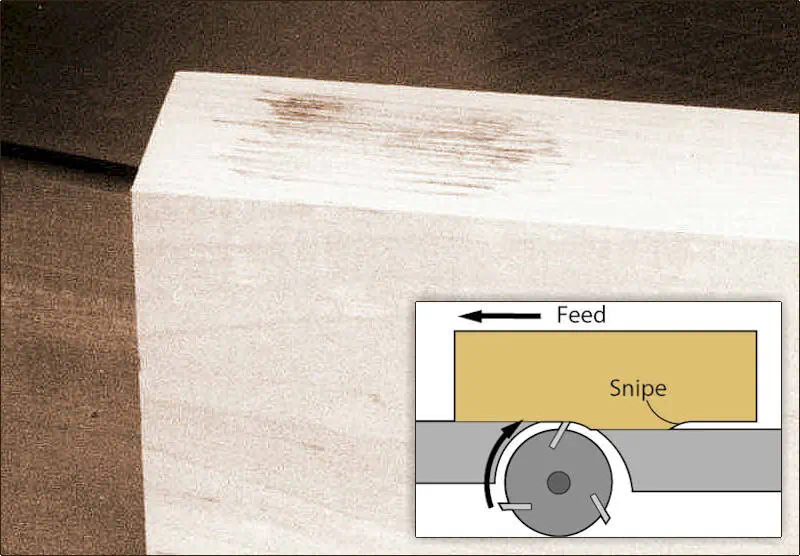

2 Turn the board around and joint the entire edge. (You should cut the snipe last.) Check the snipe — the knives should have shaved off most of the pencil marks, but they should still be barely visible. If the marks are untouched, the knives are too low in relation to the outfeed table. If they have been removed completely, the knives are too high.*