Conclusion

Pros

These hardwax oils are great for folks who are new to

woodworking, and are

safer health-wise and environment-wise than many

traditional finishes.

They contain fewer solvents, cover more surface area per

ounce, and reduce VOCs in your workspace.

The added wax offers solid water and heat resistance

while leaving behind a sleek surface with a wonderful

feel.

Considering the less toxic blends like Odie’s, Bee

Nooba, and Tried & True, hardwax oils may be among the

most durable finishes suitable for kitchens or projects

for children and pets.

They’re easy to reapply, making touch-ups a breeze, and

the soft matte finish is especially appealing in today’s

age of plastic-looking surfaces.

Cons

Averaging around US$4.00 per ounce (as of 2025), the

price of

name-brand finishes can seem a bit absurd — unless those

proprietary formulas include vacuum-boiled shark fins,

it’s hard to justify.

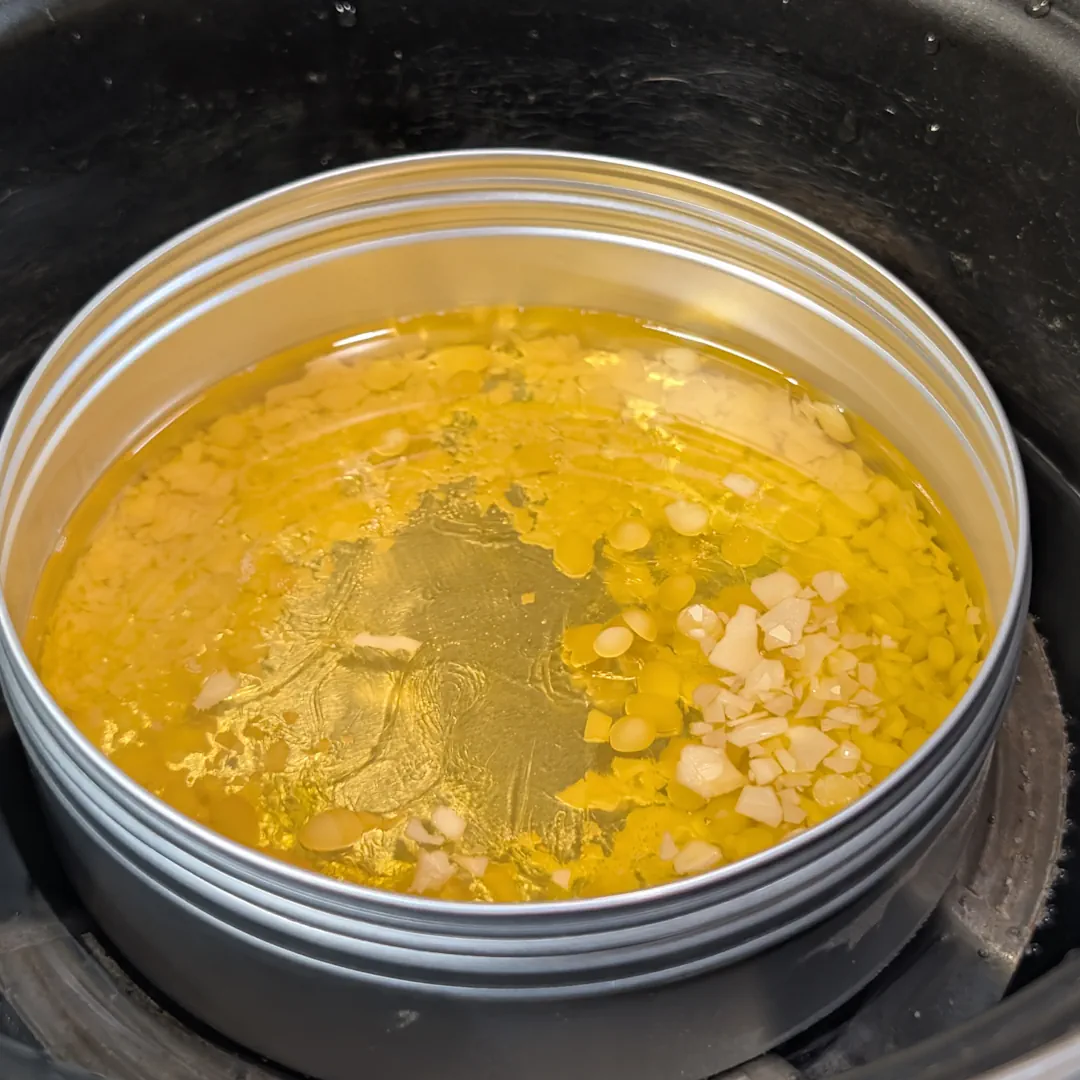

That said, I can’t be too critical — I have no idea how

Odie’s Oil achieves such a honey-like consistency while

claiming to contain no solvents.

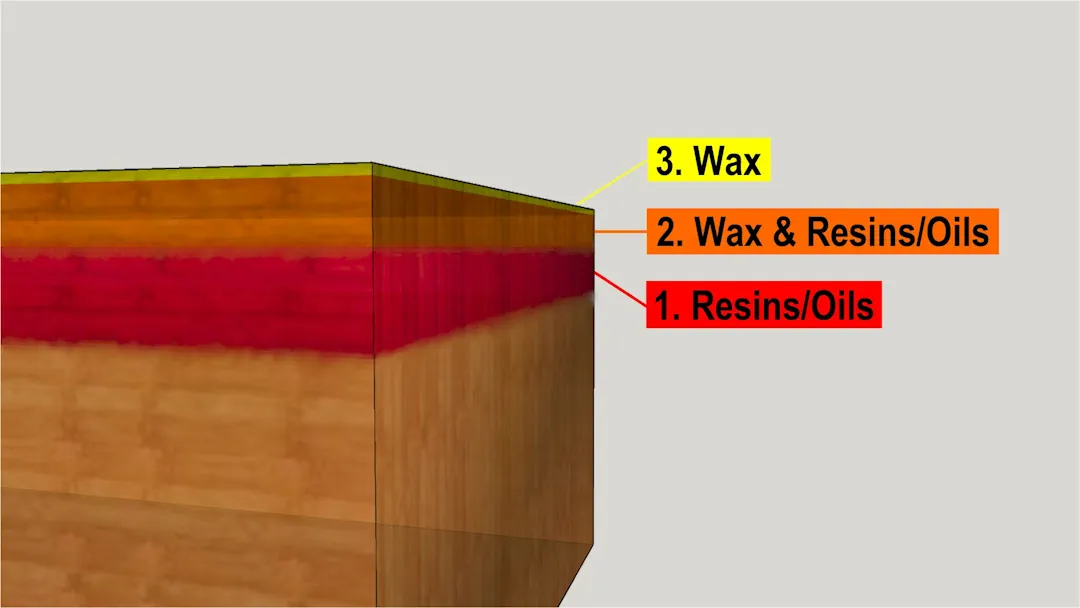

Price aside, I worry that the Transitional Layer (Oil-Wax

Interface) might make it difficult to stain your

project later. (We didn’t test this, but viewers have

reported having this experience).

Also, since hardwax oils don’t produce a protective

film, any scratches or dents go into the wood itself.

And if you're after a glossy finish, hardwax oils may

disappoint — they don’t build shine easily, and you

can’t apply most other finishes over them due to the

wax. You must purchase special topcoats.

Our Thoughts

At the end of this adventure, Nick and I both found

hardwax oils to be less versatile and attractive than

other options.

Nick will

stick with Minwax Tung Oil followed by a coat or two of

Rudy’s formula (eight parts tung oil finish to one part

spar varnish) as his go-to, and I’ll

continue using Minwax Wipe-On Poly.

Neither of us plans to buy more of the pricey hardwax

finishes anytime soon — especially after spending nearly

US$200 for very small quatities of name-brand hardwaxes

to test in our video.

But for kitchen utensils, toys, and other food-contact

or kid-safe projects, hardwax oil may very well become

our new favorite.

We’re both excited to see how our own blends holds up

over time — and we'll report the results here sometime

down the road.