GRAIN DIRECTION AND STRENGTH

To take full advantage of a wood’s strength, pay attention to the grain direction. Wood is a natural polymer — parallel strands of cellulose fibers held together by a lignin binder. These long chains of fibers make the wood exceptionally strong — they resist stress and spread the load over the length of the board. Furthermore, cellulose is tougher than lignin. It’s easier to split a board with the grain (separating the lignin) than it is to break it across the grain (separating the cellulose fibers).

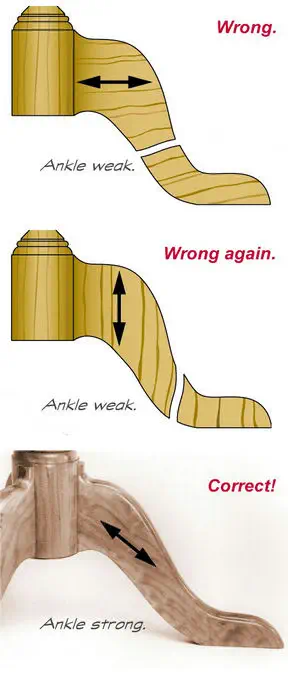

Remember this when you lay out the parts of a project. Always orient the grain so the fibers support the load. Whenever possible, cut the parts so the grain is continuous, running the length of the board. This also applies to wood joinery! When cutting a tenon, for example, the wood grain must run the length of the tenon and the board so the grain is continuous.

The wood grain in the legs of this pedestal table runs parallel to the longest dimension to make the legs as strong as possible. Were the grain to run parallel or perpendicular to the pedestal, the legs would be weak at the ankles.