BUSTING DOWN LUMBER

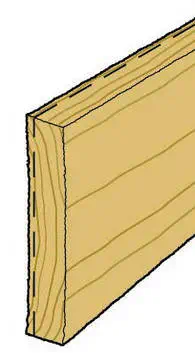

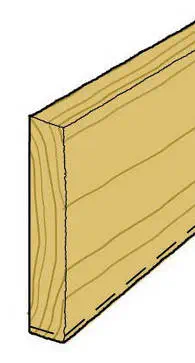

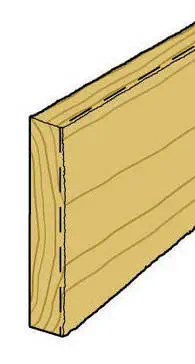

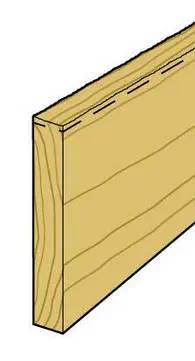

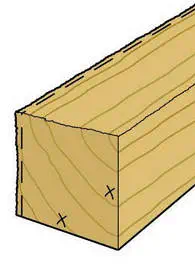

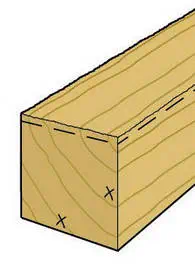

Start with thoroughly shop-dried stock. Measure and mark the parts of your project on the boards. As you do, leave extra stock, making the parts 1 to 2 inches longer and 1⁄2 to 1 inch wider than their final dimensions. Cut and rip the boards, roughing out the parts.

Craftsmen refer to this as "busting down" rough lumber, and it relieves stresses in the wood. As the tree grows, it often buttresses itself against wind or gravity. Drying may create further stress. These internal tensions remain until you release them by cutting the wood apart. As they are released, the wood moves slightly. But since you’ve cut the parts oversized, you have the extra stock needed to true them.